| Indeed if pinch roller is not making good contact(slipping), it can prevent tape movement. Judging by the age of unit, probably could use a replacement rather than cleaning--bet it has a shiny surface and rather hard as a rock. Sometimes, when you try to clean it, depending on the condition of the rubber, you may actually make it worse. One way to verify; If and when it begins to malfunction, try adding slight pressure against it where it engages the tape & capstan motor shaft. |

|

| RE: Half loader arm - I believe I see which one you're talking about, and yes it is quite free. Ths is a metallic piece mounted to the transport chassis assembly? OF so then I've got it. I watched the tape load process and anything that looks like it is supposed to move easily does so. I have been transferring a tape to digital for a client and since repacking the tape (running it through several times) it doesn't appear that there is any transport issue - at least anywhere mid tape or after ejecting and re inserting tape. The pinch capstan on the right however is definitely in need of cleaning. Could be that it's just slipping? Would be interesting, and I think I'll try that momentarily, if rewinding to the very beginning ( or using an tape previous not watched) causes the probelm to resurface. |

|

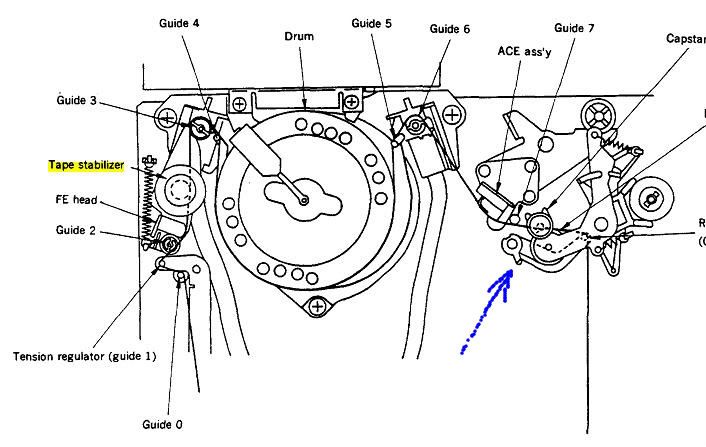

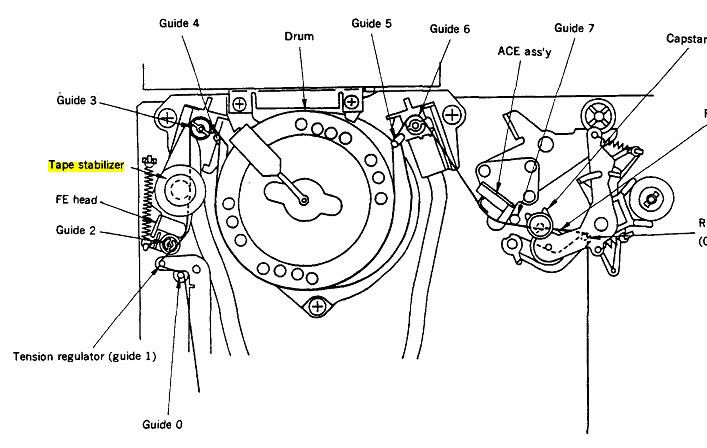

| If you were to scope the video envelope, you'd notice that it really has no major effect and as far as wow & flutter, while you are correct about stationary audio heads, it is not a problem with Hifi audio that is being picked up by part of spinning video head. In general, once tape has past the #3 guide roller, it is insignificant. As far as the txport problem, there are several possibilities; you mentioned having to shuttle the tape back& forth which sounds like it may be tarnished contacts in mode select switch. However, before going that route, when loading a tape inside the carriage, does it sit all the way down completely without any slack? (spring loaded ) Also, another very common issue was the half loader arm(blue arrow) binding caused by grease drying up at it's pivot point. Is it free to move through it's range? Without a tape inside, you should easily be able to swing it as it springs back. --if it is binding, do not attempt to remove it.  |

|

| Thanks! The machine had played this way for several years - with the tape stabilzer missing. I've hung on to it figuring one day I'd either take it in or try and figure it out myself. The location on the diagram is the only one that made sense to me also, I tried to guess where it may have come from, and this time at least I guess correctly. I'm quite surprised that it could just fall of as it was pretty snug sliding over the shaft to put back on. I noticed that without the stabilizer in place that on each rotation of the plastic shaft the tape would wobble as a little bump hit the tape. I understand a little bit about tape operation, and introducing wow or flutter doesn't seem to be the right thing to do, so that's where I installed that piece. It was also the only shaft that this piece would slide over. Now that that is solved. Any thoughts on my other transport issue - that being when you first insert a fresh tape or one that is completely rewound It takes some shuttling of the buttons [play], [rew], [fwd], [play]...etc... to get the tape to play. one it starts playing all transport works perfectly. The best thing I've fund is not to rewind to STOP. I thought this might be a tension adjustment or brake issue... |

|

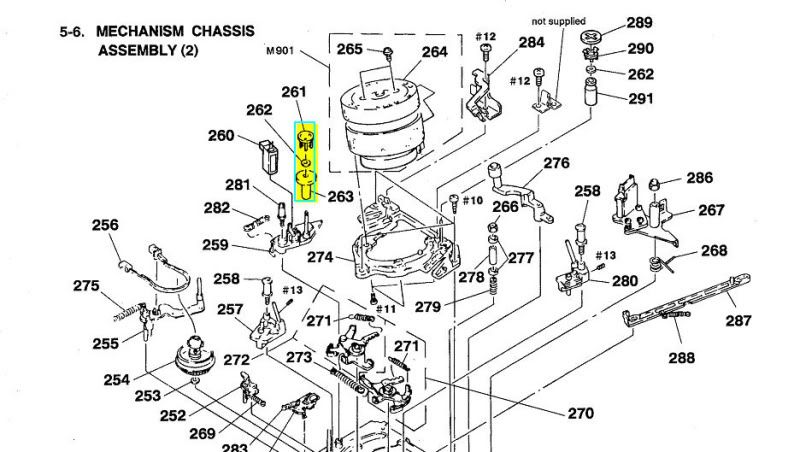

That is called a tape stabilizer and has very little effect--if any on playback. Just a free wheeling roller. Meant to smooth out tape travel mainly for search modes. It basically snaps in place on a thin shaft and retainer(262) suppose to hold it down but it may split & pop out. Generally happened when the unit was turned over. Suspect you may have other problem(s) if not playing. You can post a picture by using the img tag. Couple of pictures, one from SLVR100 which used the identical txport and one from the mech adj II manual.   |

|

| CLICK for PIC | |

| Can I upload a picture or attach one here? | |

| Don't have a manual but am very familiar with that unit. That is from a generation where the transport was actually designed by Hitachi as Sony was getting in to the VHS market and a rather reliable Txport. With little revision, it was used on many different models including their top of the line SLVR1000. There were several issues with the mechanism, most of which had to do with brittle plastic cracking mainly due to age. Also there were other issues with tape guide(sounds like what you have), half loader etc. Can you post a picture of the piece? |

|

| I've had this VCR deck for years. One of the best decks I've ever had. After being in storage for some time it had developed a weird habit of wanting to eject the tape (any tape) when it's first inserted. You have to mess with transport functions to get it to play, but it does play. I figure the ejection is do to a tension adjustment, so I too a peek inside. There was a part plying loose in the machine. I need to manual to figure out where in the tape path this came from. It has a steel shaft /tube with a round brass weight about the thickness of a nickle, about the size of a dime on one end. On top of that is a plastic piece that has three catches that pass through the brass piece. I'm sure with that description no one would be able to tell me what it is, thus why I need a manual. Thanks! |

|